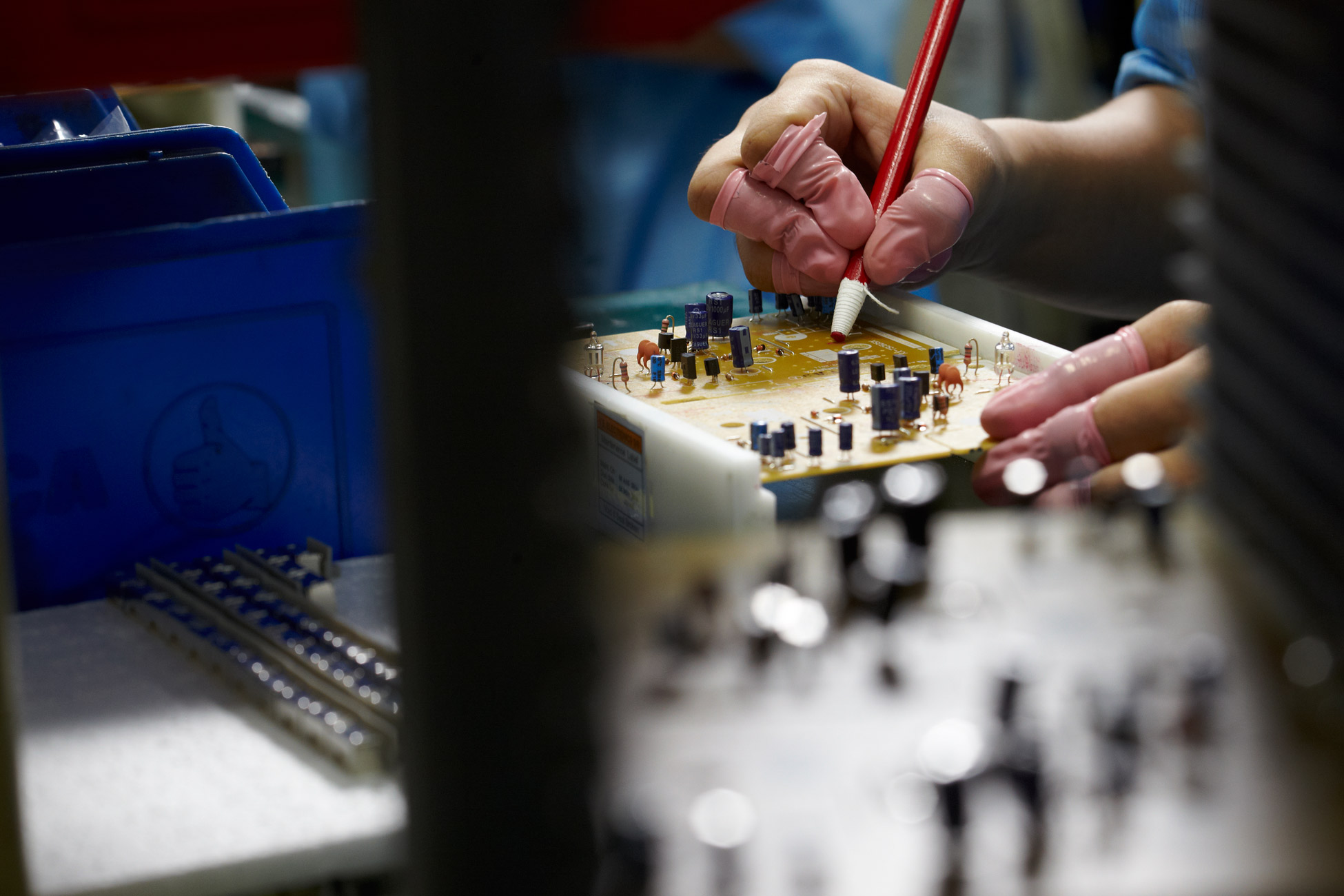

Printed Circuit Board Assembly (PCBA) Services

Support full supply chain management and quick turn for prototype build as well as mass production build

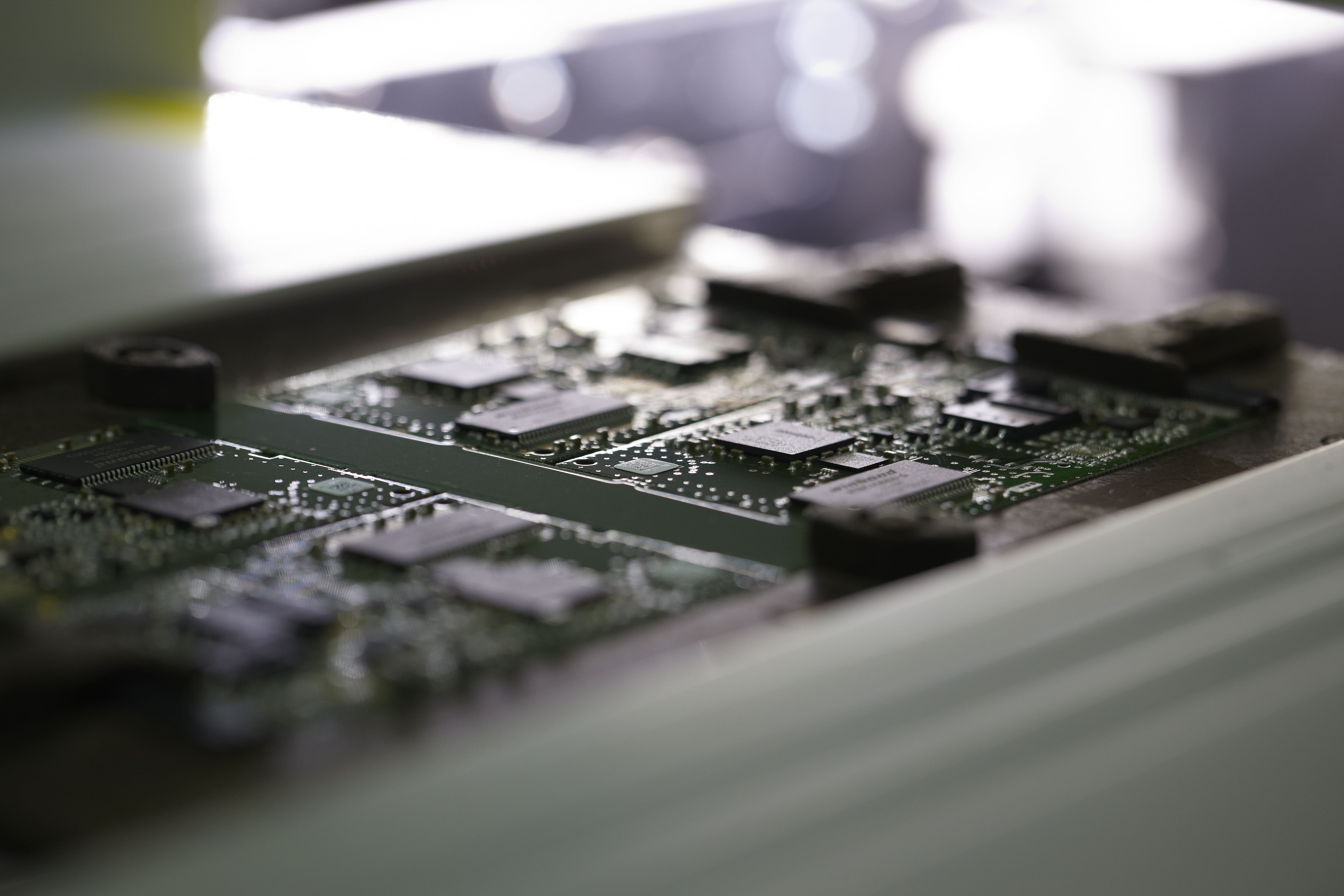

Beyonics supports complete printed circuit board and box-build assembly, and can help clients in both high mix low volume and low mix high volume productions.

Leveraging our specialized manufacturing campus in Malaysia, we operate 40+ high speed SMT lines to simultaneously accommodate both rapid prototype development and high-volume production demands.

Through a unique combination of engineering, design and manufacturing

PCBA

Process

- Receiving & Kitting

- SMT Assembly

- Wave Solder

- Depanelize

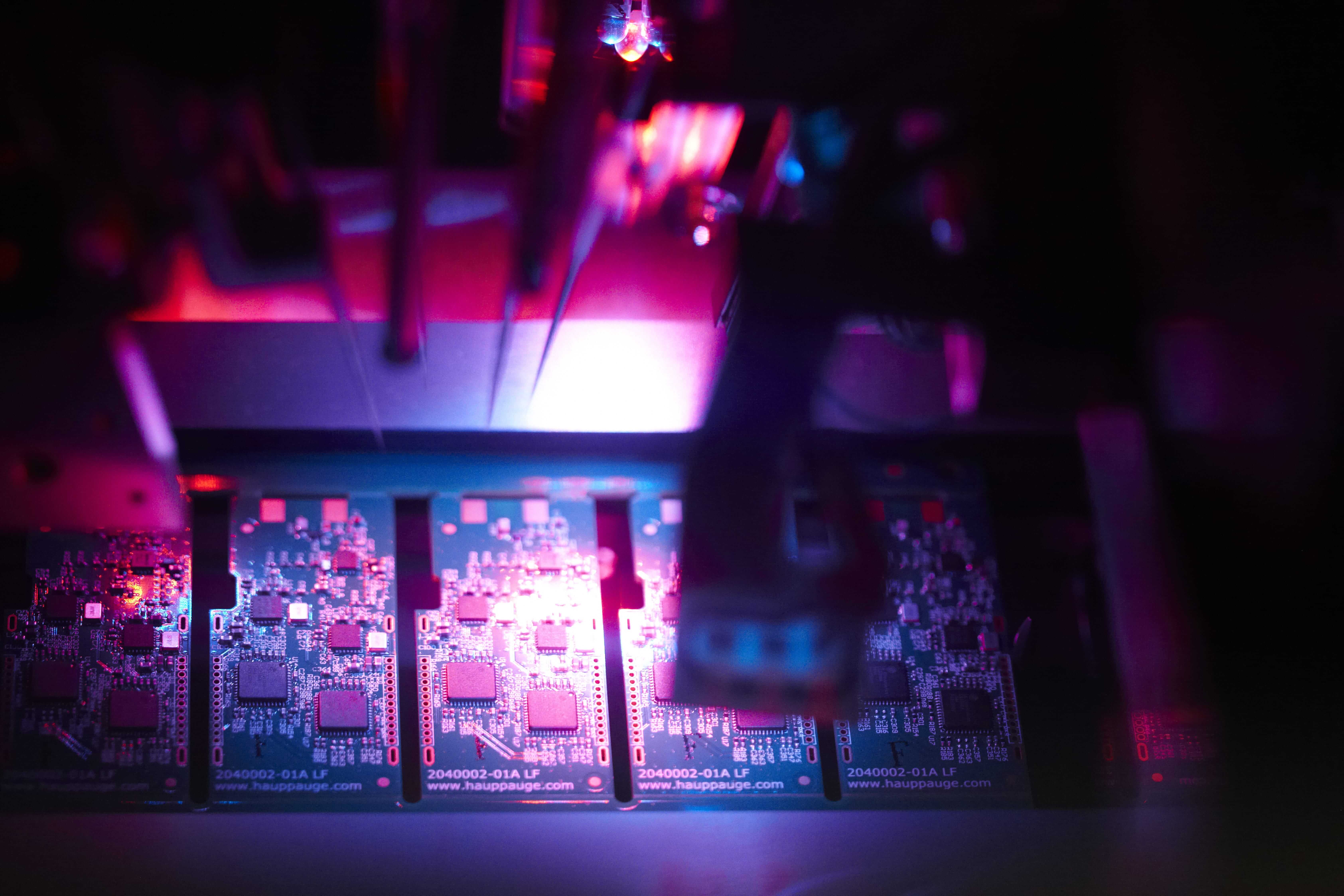

- Testing

- Inspection

- Packing

- Finished Goods and Shipping

PCBA

Testing

- In-circuit Test: Agilent test station for large volume mass production.

- Flying Probe: Applicable for High Mix Low Volume production and NPI build.

- Functional Test: Work with customer to develop test plans and testers for functional testing.

Quality

Assurance

Beyonics, a renowned manufacturer in the field of Printed Circuit Board (PCB) assembly, adheres to several certifications and standards to ensure the highest level of quality and reliability in its manufacturing and validation processes. These certifications play a crucial role in establishing the company’s credibility and demonstrating our commitment to meeting industry standards.

- ISO 13485: 2016

- ISO 14001: 2015

- ISO 45001: 2018

- ISO 9001: 2015

- IATF 16949: 2016

- Electronics Assembly: IPC-A-610

- C-TPAT Custom Trade Partnership Against Terrorism

- Batch Traceability System: In -house Shop-floor Management System