Plastic Injection Molding Services

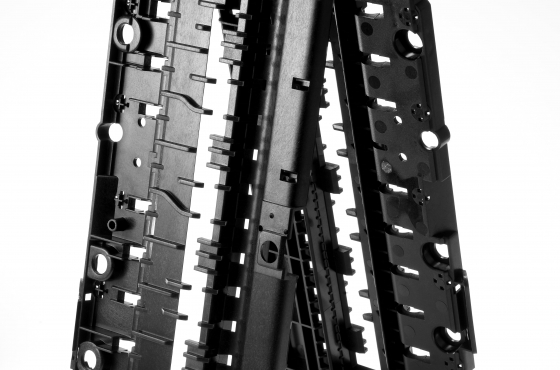

As a leading injection molding supplier in the industry, Beyonics offers vertically integrated services, from mold design and fabrication, and can help clients produce high-precision plastic parts in high mix low volume and low mix high volume, supplemented by value-added services, such as mechanical and electrical assembly services, in-house Polymer Solutions etc. Plastic injection molding is one of our strengths.

Plastic Injection Molding Services

As a leading injection molding supplier in the industry, Beyonics offers vertically integrated services, from mold design and fabrication, and can help clients produce high-precision plastic parts in high mix low volume and low mix high volume, supplemented by value-added services, such as mechanical and electrical assembly services, in-house Polymer Solutions etc. Plastic injection molding is one of our strengths.

Plastic injection molding is a widely used manufacturing process that involves the production of plastic parts by injecting molten plastic material into a custom-designed mold. It is a highly versatile method capable of producing complex and intricate shapes with precision and efficiency.

The Process of Plastic Injection Molding

The production process begins with the creation of a mold, typically made from steel or aluminum, which is designed to match the desired shape and features of the final plastic part. The mold consists of two halves, the cavity, and the core, which form a hollow space in the shape of the desired part. The mold is precision-engineered to ensure proper filling, cooling, and ejection of the plastic.

During the injection molding process, plastic pellets or granules is melted and injected into the mold cavity under high pressure, taking on the shape and details of the mold.

The plastic is then cooled and solidified, allowing it to retain the molded shape. Once the plastic has solidified, the mold is opened, and the newly formed plastic part is ejected. The cycle can be repeated continuously to produce a large volume of identical parts.

Precision injection molding offers several advantages. It allows for the production of complex geometries, intricate details, and tight tolerances. It is a highly efficient process, enabling the production of many parts in a relatively short time. The process is also cost-effective, as it minimizes waste and allows for material and energy savings.

Injection Molding Applications

Plastic injection molding has extensive applications across various industries.

Healthcare / Medical device injection molding

Surgical Devices, Hearing Aids, Glucose Infusion Meters, Syringes, and Contact Lens Case etc. (certified to ISO 13485).

The process of healthcare / medical injection molding ensures the production of high-quality and biocompatible medical components that comply with stringent regulatory standards. Healthcare / Medical device injection molding plays a critical role in enabling advancements in healthcare by delivering safe, reliable, and cost-effective solutions for various medical applications.

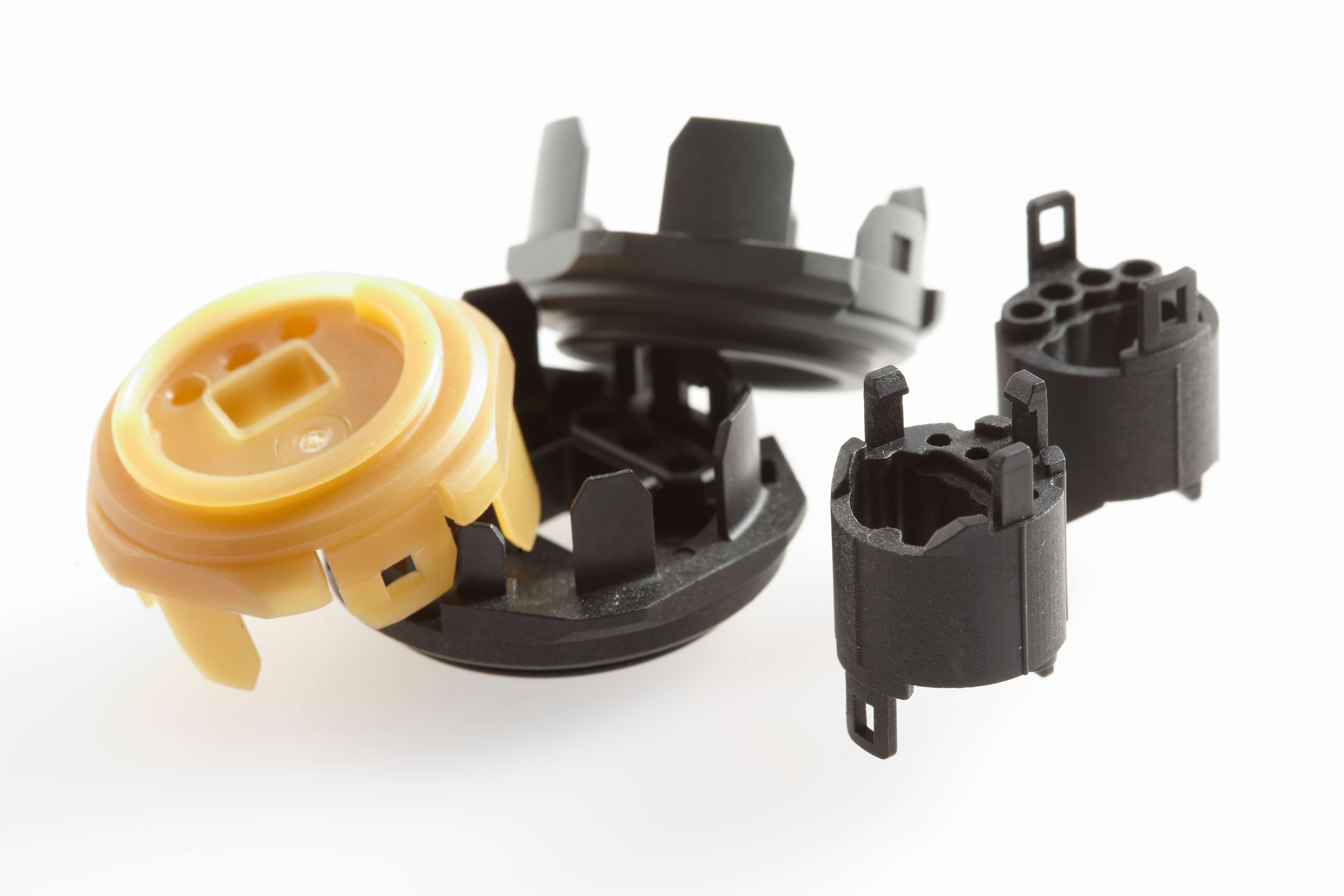

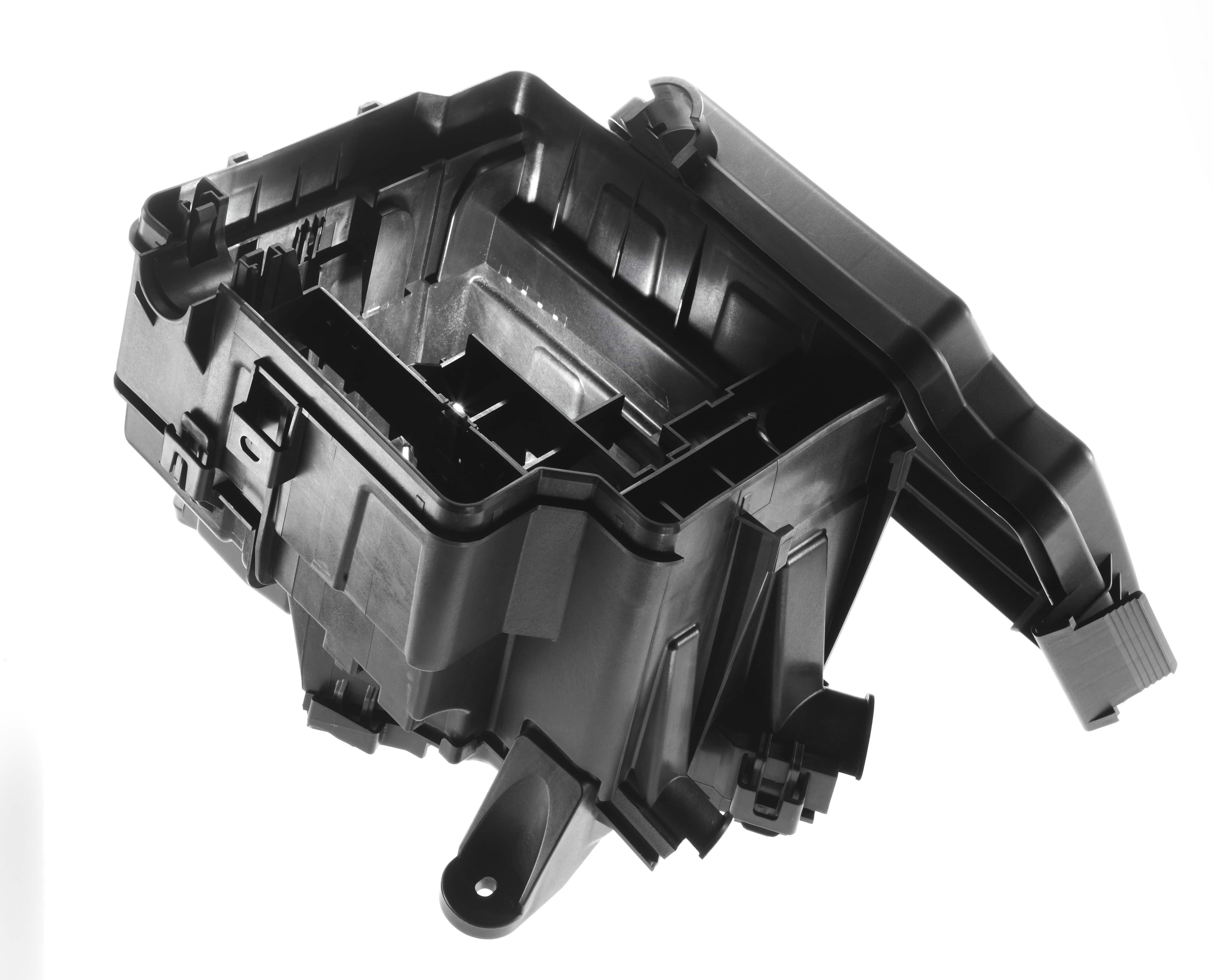

Automotive industry

Advanced Driver Assistance Systems (ADAS) which include automotive sensors and components, navigation systems, automotive LiDAR, forward-facing Camera, and fuel injection connectors, ECU housings, and EV applications etc. (certified to IATF 16949).

The automotive industry demands precision, durability, and aesthetic appeal, all of which can be achieved through injection molding. This process allows for the creation of complex shapes and intricate designs, ensuring precise fit and function of the components produced. It enables consistently zero-defect-quality, high volume production parts while reducing costs and ensuring timely delivery. The use of different materials, such as reinforced plastics, enhances the strength and durability of automotive parts, meeting rigorous performance requirements.

The versatility and wide-ranging applications of plastic injection molding make it an indispensable manufacturing process for numerous industries seeking high-quality, cost-effective, and customized plastic parts.

Through a unique combination of engineering, and construction

Injection

Molding

Machines & Materials

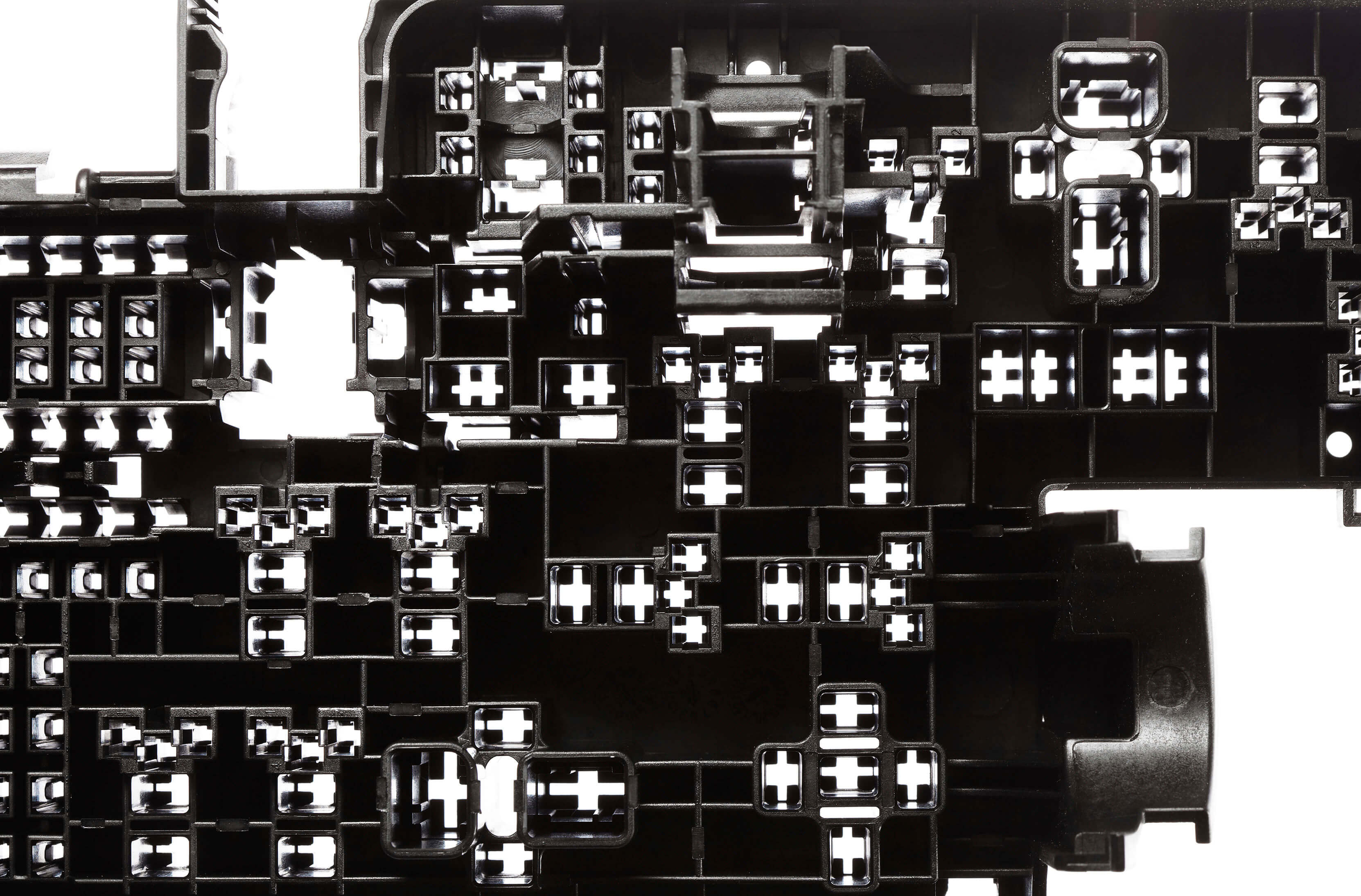

- Equipped with 15 – 1,600 ton injection machines;

- Vertical molding machines (Up to 1 Cav/3 Core

- Horizontal molding machines (High speed) for 2K molding, glass insert molding, Teflon molding etc.

- Able to handle resins from common PP, ABS, PC, PCABS, PA etc. to more complex engineering plastics for example PPS up to 65%GF, PEI, PEEK, PFA etc.

- Fully and semi-automated insert molding with visual checking integration

- Fully and semi-automated insert molding with visual checking integration

Secondary / Additional Process

- Heat-staking, ultrasonic welding, laser-marking, connector assembly, glue dispensing and gasket-dispensing capabilities, reagent management (storage/filling).

Value-added solutions

In-house Polymer Solutions

- Beyonics utilizes in-house polymer solutions to provide a wide range of bespoke polymer products made to customer design specification. Driven by Environment care, quality control, supply stability & value creation, Beyonics engineer High Performance Thermoplastics Compound for Total Solution, Quality, Supply & Cost in mind.

Certifications for Manufacturing and Validation

- ISO 45001:2018

- ISO 9001: 2008

- ISO 13485

- IATF 16949

- Clean Room 8

- FDA audited production site

Quality

Assurance

- Full Test Lab that diagnoses cleanliness, contamination of processes, parts, and systems

- Quality Assurance Laboratory with full-fledged equipment such as smart-scope, CMM, and different testers