Metal Tooling Solutions

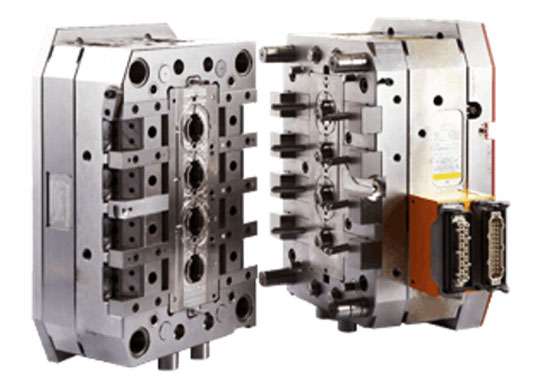

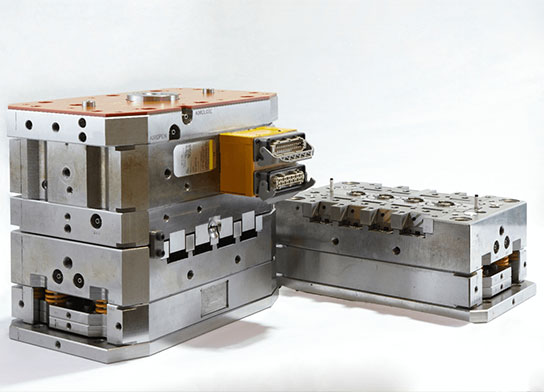

At Beyonics, we deliver custom-engineered metal tooling solutions that support high-precision manufacturing processes. Our capabilities span from early-stage design to full-scale production, offering strategic support for aluminum die casting, plastics injection molding, and hybrid tooling applications. With facilities across Asia, we serve global clients in the MedTech, Mobility and SmartTech sectors.

Metal Tooling Solutions

At Beyonics, we deliver custom-engineered metal tooling solutions that support high-precision manufacturing processes. Our capabilities span from early-stage design to full-scale production, offering strategic support for aluminum die casting, plastics injection molding, and hybrid tooling applications. With facilities across Asia, we serve global clients in the automotive, medical, and industrial sectors.

Our in-house engineering teams collaborate with customers to develop efficient, scalable, and quality-focused tooling systems. From low-volume prototypes to high-volume production runs, we offer the flexibility, experience, and innovation required in today’s competitive manufacturing landscape.

Applications

- Sequential mold, stack mold, 2K injection mold, insert mold, outsert mold, overmold, unscrew mold, etc.

- Large automotive and medical enclosure and cosmetic tools up to 450 tons clamping force.

- Precision tools and gears up to AGMA 8 (Din 9 or JIS 5).

- Molds for small precision to large parts from 15 to 1600 tons.

- Parts with wall thickness of less than 0.18 mm.

Beyonics continues to expand capabilities in complex metal tooling for automotive industry parts and high-performance medical components. Our advanced high-strength steel and carbon steel solutions enable high-volume production with exceptional accuracy. With extensive experience in tool and die manufacturing, we deliver progressive die and sequential mold systems tailored to challenging applications.

Through a unique combination of engineering, design and manufacturing

Engineering

Services

Beyonics' engineering team provides strategic guidance across the full production process—from concept to production tooling. We apply sheet metal work principles, simulation-based design, and automated tooling systems to ensure cost-effective, scalable outcomes.

- Design for Manufacturing (DFM)

- Early Involvement

- Mold Flow Analysis

- Customized Automation

Tooling

Technology

To meet the increasing demands of custom metal fabrication, we utilize advanced fabrication tools and machine tools to support full production cycles. Our metal tooling facilities in Singapore and Malaysia are equipped with punch press systems, press brakes, and laser cutting stations capable of handling progressive tooling tasks at scale. As trusted metal tooling manufacturers, we invest in continuous upgrades to meet evolving standards for metal parts precision.

- Makino, Charmilles and Sodick wire-cut / CNC machines for precision injection mold fabrication

- Makino / Charmilles EDM machines

- 5-axis milling, grinding and super drill machines

- Coordinate Measuring Machine (CMM) and optical scopes in the metrology lab

- Unigraphics NX 3D software for mold design and Computer-Aided Manufacturing (CAM) programming

- Autodesk Moldflow Insight for simulating plastic flow analysis before finalizing mold design and production to enhance manufacturability and product quality

Quality

Assurance

Our rigorous quality control ensures every tool meets the demands of modern machining industries. From carbon and stainless steel assemblies to aluminum die casting, we guarantee process reliability.

- ISO 9001

- ISO 14001

- ISO 13485

Why Beyonics Is the Trusted Name in Metal Tooling

With decades of expertise, Beyonics stands among the top metal tooling manufacturers in Southeast Asia. Our operations in both metal tooling Singapore and metal tooling Malaysia hubs deliver industry-leading results through our integrated tooling, engineering, and production infrastructure. We specialize in precision metal stamping, custom tooling, and CNC-driven metal fabrication solutions tailored to your performance needs.

Why clients choose us:

- Full in-house design, engineering, and fabrication capabilities

- Quick turnaround from concept to full production

- Advanced tooling for precision parts and mass manufacturing

- Proven track record across multiple sectors

- Industry pioneers in automated and custom tooling solutions

We don’t just build tools—we engineer solutions that streamline your manufacturing process. From prototyping to high-volume progressive dies, our team ensures on-time delivery and dimensional accuracy with every build.

Industries We Serve with Confidence

MedTech

From diagnostic equipment housings to miniature implant-grade components, our tooling supports medical-grade requirements with ISO 13485-certified processes. Stainless steel and precision parts are crafted to support critical medical production.

Mobility

We produce complex tools and dies that support the manufacture of automotive industry parts such as engine housings, sensor components, brackets, and enclosures. Using advanced high-strength steel and progressive dies, we ensure high-volume output with exceptional accuracy and repeatability.

SmartTech

For brands seeking lightweight yet durable components, we provide tooling for sheet metal work, aluminum die casting, and plastics, with fine tolerances and smooth finishes to support sleek and functional designs.

Let’s Build Your Next Breakthrough Together

From concept to completion, Beyonics is your trusted partner in metal tooling. Whether you’re scaling up for mass production or developing intricate prototypes, our team delivers innovative tooling solutions tailored to your needs.

Talk to our experts today to explore how we can elevate your manufacturing process with world-class metal tooling services.

Contact us now to start your project with industry-leading precision and reliability.